Our Services

Machine Shop Capabilities

Our quality department inspects every process through final completion, utilizing the best measuring equipment and inspection tools in the industry.

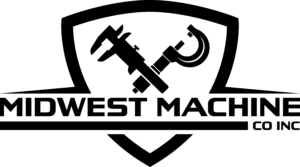

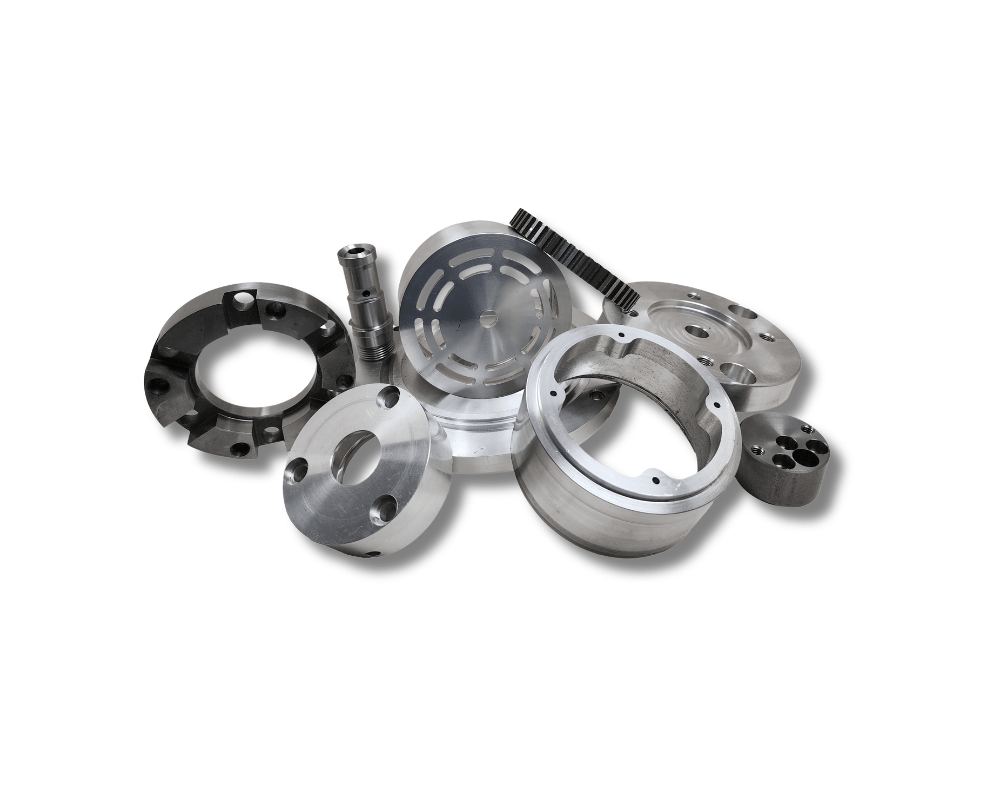

PRECISION TURNING

We offer numerous CNC Lathes with thru diameters of ¼”-2” bar feeding capacity as well as chucking for jobs up to 10”

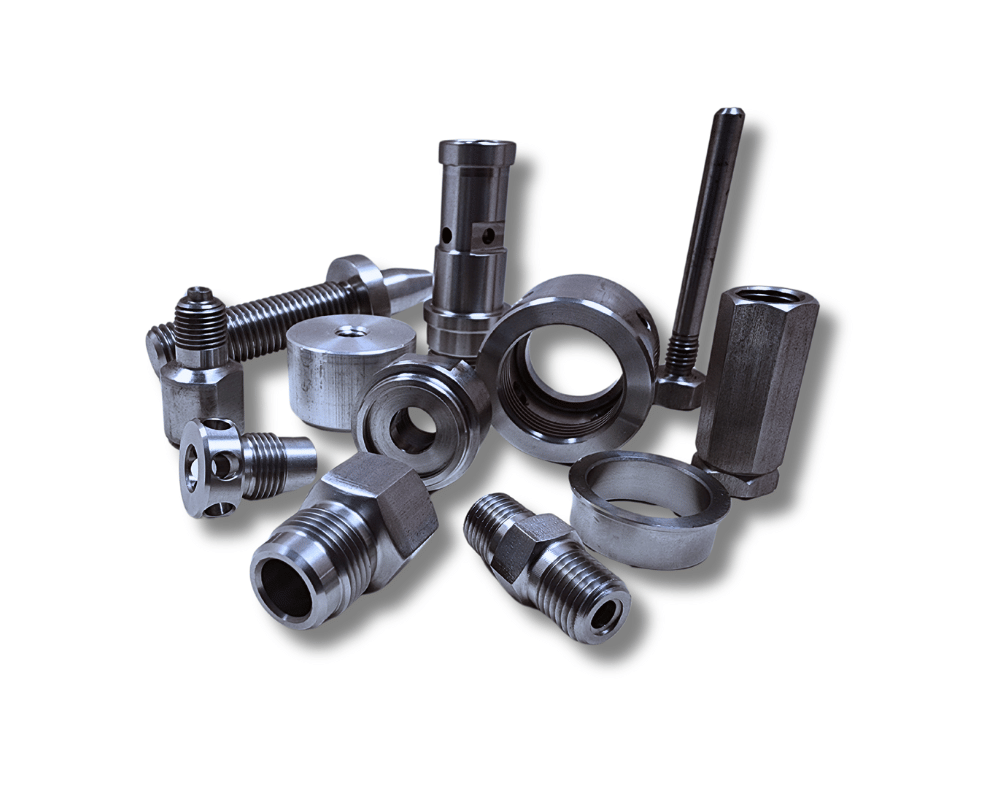

PRECISION MILLING

We offer three sizes of Vertical CNC Mills to handle jobs up to 12” x 32”

MILL TURN W/ LIVE TOOLING & SUB SPINDLE

Our Okuma Genos LB3000-MYW can produce completed milled and turned parts with one set up maintaining tolerances of +or- .0005”

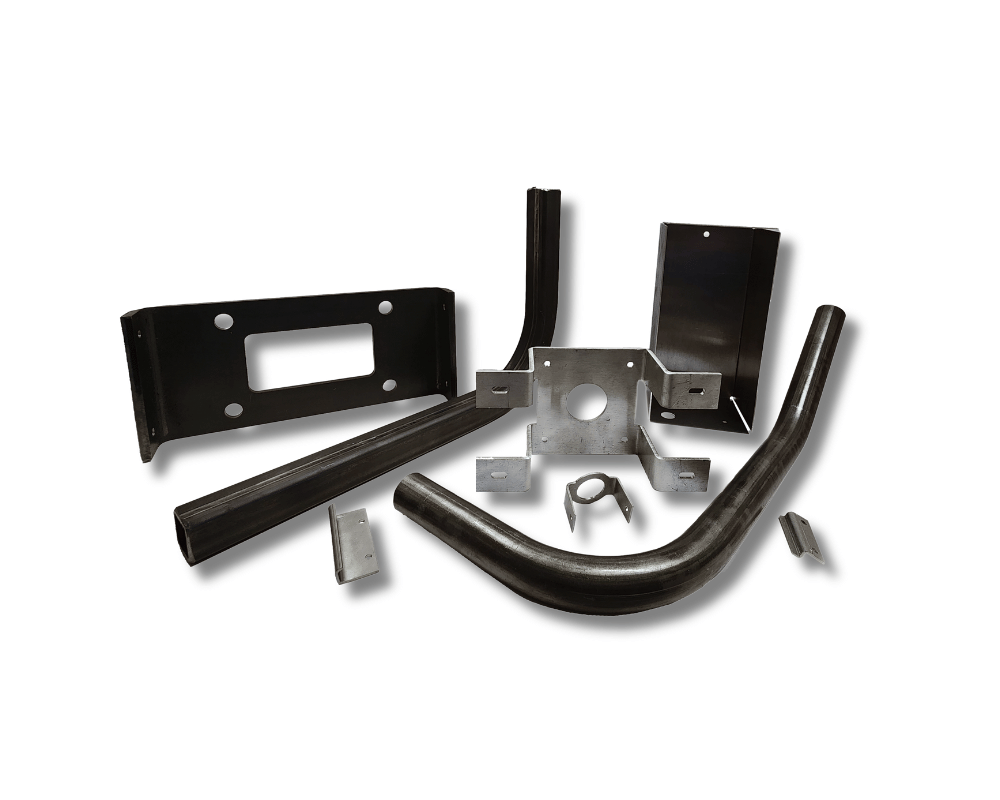

WELDING & FABRICATION

Our shop is capable of handling high quality mig and tig welding of various alloys including but not limited to: stainless steel, aluminum and cold rolled steel. We can manufacture our own fixtures when needed.

BENDING & FORMING

We offer Tube & Pipe Bending up to 3” O.D. We offer a large variety of punch and break presses to bend and form your parts for most applications.

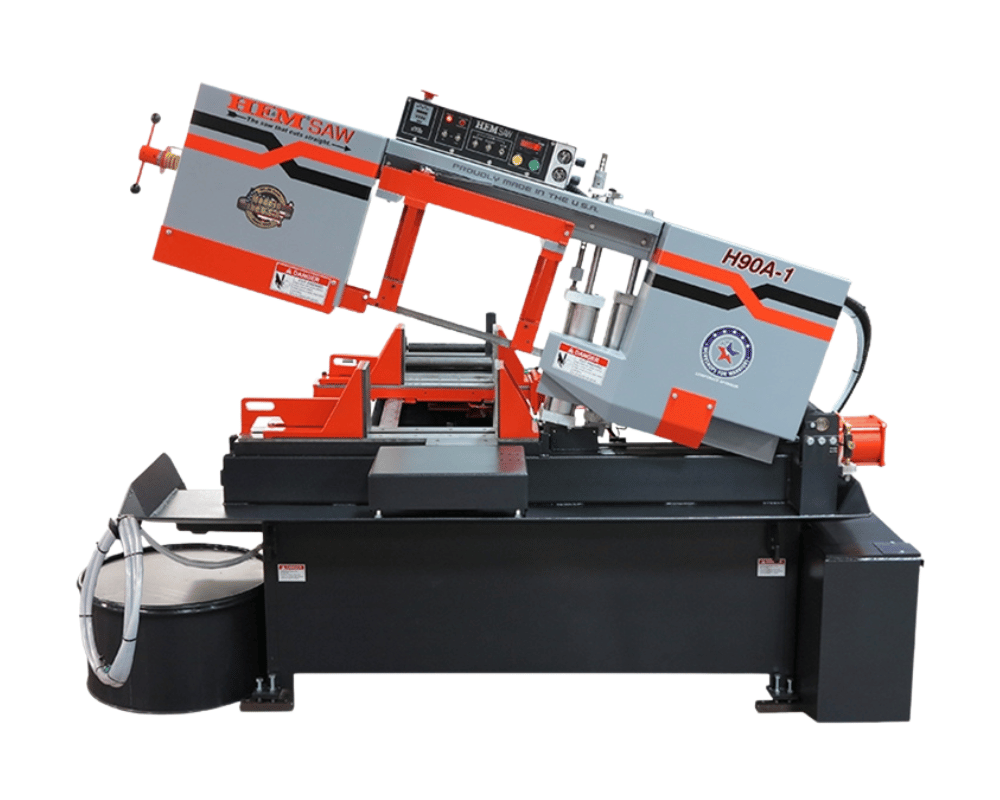

SAWING & CUTTING

Two Hem Saw automatic horizontal band saws cutting up to 12”x12” Top notch plasma and oxy cutting done in house.

CENTERLESS GRINDING

Centerless grinding ranges from 1/8” thru 3” auto feed on multiple types of materials with Surface finishes of RA 12 or better holding tolerances of .0003” Plunge Grinding up to 1-1/2” Diameter x 4” length with finishes of RA 12 or better holding tolerances of .0003” Burnishing for mirror like finish RA 8 or better ranging from 1/4" to 5/8” Diameters.

FAQ

What types of machining services do you offer?

Midwest Machine Co Inc offers various metalworking services, including precision turning, milling, mill turn with live tooling and sub-spindle, welding and fabrication, bending and forming, sawing and cutting, centerless grinding, and more. These services cater to complex part manufacturing, intricate milling tasks, efficient mill-turn operations, custom metal structures, precise sheet metal shaping, accurate cuts, consistent cylindrical grinding, intricate profile creation, and improved surface finish.

What is the turnaround time for a project?

We understand the importance of timely delivery. While every project is unique, we work diligently to meet agreed-upon deadlines. Our team collaborates closely with customers to ensure that projects are completed efficiently and according to schedule.

Do you offer custom machining services?

Yes, we offer mid-high volume machining services to cater to your specific requirements. Our skilled machinists and engineers work closely with customers to transform their design concepts into tangible parts and components. We have the expertise to handle complex geometries, tight tolerances, and specialized materials.

What is your pricing structure?

Our pricing structure is based on several factors, including the complexity of the project, materials used, quantity required, and turnaround time. We provide competitive quotes tailored to each customer’s needs, contact our sales team to learn more today!

Do you have a minimum order quantity?

Our focus is primarily on mid-high volume order quantities. However, we are open to discussing specific requirements and finding mutually beneficial solutions.

What are your quality control procedures?

We prioritize quality in every aspect of our operations. Our quality control department adheres to stringent procedures and utilizes advanced measuring equipment and inspection tools to ensure that all parts meet or exceed customer specifications. We are committed to delivering products that consistently meet the highest standards of quality.

Do you offer delivery services?

Our services extend beyond Kansas City and the Midwest, reaching clients throughout the United States. To inquire about delivery options and potential variations based on your location, please don’t hesitate to contact us.

What are your hours of operation, and how can I contact you?

Our regular business hours are Monday through Friday, from 8:00 AM to 4:30 PM. You can reach us by phone at (816) 461-4433 or by email at [email protected]